<strong>RoastR</strong> is developed for producing tomorrows fresh, vegetable-based, snack pellets. The gentle roasting process makes sure that nutrients are preserved in the finished product, where the content of vitamins and dietary fibers can be kept high. At the same time the fat content in the finished product is as low as <strong>0%</strong> and the protein content ranges up to <strong>40%.</strong> A wide range of today’s standard pellets can of course also be produced with RoastR.

Read more

The <strong>Rosenqvists</strong> nut frying system are suitable for all types of nuts and seeds. The fryer is excellent for coated nuts. Depending on the final product, the frying system is equipped with the suitable type of belt, oil filtration system and possible need of a top submerger belt to ensure production and final product quality.

Read more

To produce a high-quality product when frying snack pellets you will need more than just a great frying system. You will need a complete processing line that can ensure an even flow of product throughout the process.

Read more

Rosenqvists Food Technologies has extensive knowledge of the potato as raw material and how to design an effective process. We combine the latest technologies using computer simula-tion programs and build efficient and reliable process equipment. We take responsibility for design, manufacture and installation. We will commission the line and make sure that your staff get professional training in maintenance and process control.

Read more

Through experience Eillert knows that it is important to adjust the washing process to any product. The wide range of adjustments of the <strong>WASH makes</strong> this series very widely usable. Both floating and non floating products can be washed. The specific adjustments of the vegetable washing machine can be performed both manually and PLC controlled.

Read more

The <strong>preparation tables with two levels</strong> are identical to those with one level, however, on this table the vegetable waste is removed via a transport belt that discharges in the opposite direction of the slicing machine. A possible option could be a waste belt with an elevator to transport the waste in cubic crates.

Read more

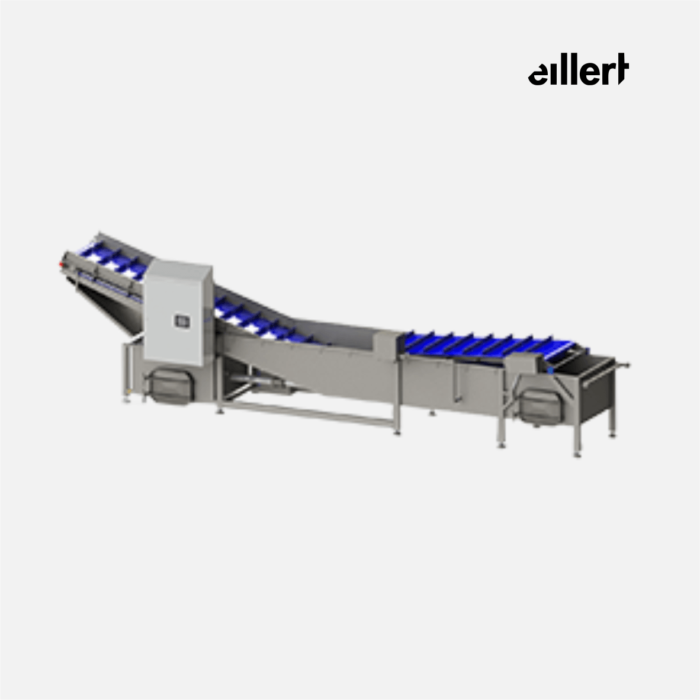

The <strong>Eillert belt drying system</strong> is carried out with blower units, of which the strength of the air flow can be set to the exact need. The belts are widely usable for many products (tomatoes, cucumbers, paprika) in a range of capacities.

Read more

For washing and disinfecting of fruit and uncut products, Eillert has developed several solutions. As most kinds of fruit (pineapple, melon, oranges, apples etc.) and uncut products (tomatoes, cucumbers etc.) float, a dipping belt is used. The <strong>dipping system</strong> ensures that products that normally do not immerse completely are carefully brought under water.

Read more

The industrial <strong>cabbage slicing machine</strong> CSM is constructed with a wide infeed gutter, which feeds the (decored) cabbage onto the special cutting disc.

Read more

The <strong>automatic vegetable centrifuge ASD</strong> is developed to automatically process several types of vegetables. After the product has been washed, it is brought directly onto the infeed belt. This infeed belt is also used as a buffering belt. During the infeed of the product, the centrifuge drum moves evenly to the back as a result of which a good dosage is obtained in the drum. After that it accelerates and the product is centrifuged. As soon as the centrifuging cycle has been concluded, the drum speed is reduced and the product is gradually discharged onto the outfeed belt.

Read more

The <strong>floatation washer</strong> can be used instead of the drum washer, to effectively wash your product.

<strong>This machine works as follows:

</strong>The products are fed into the washer where spray nozzles located at the top and bottom of the tank cause a current. This current cleanse the product causing the various debris to be separated from the flow. The sloped in-feed tank causes this debris to settle at the in-feed end for easy removal. A mesh wire discharge conveyor removes the product from the water and introduces it to a further cleansing fresh water spray.

Read more

<strong>Air separator</strong>

After the reception you can pre-clean the beans before the product goes to the de-stoner. This machine is custom made to fit into the line with the correct capacity.

The air separator works as follows: The product is conveyed onto the infeed pan where it is evenly distributed through the oscillation of the shaker. It is then fed into the Air Cleaner where it passes over a jet of air created by the bottom mounted fan. This allows for the good product to continue through the Air Cleaner while any debris is lifted up and out of the product stream for immediate removal.

Read more