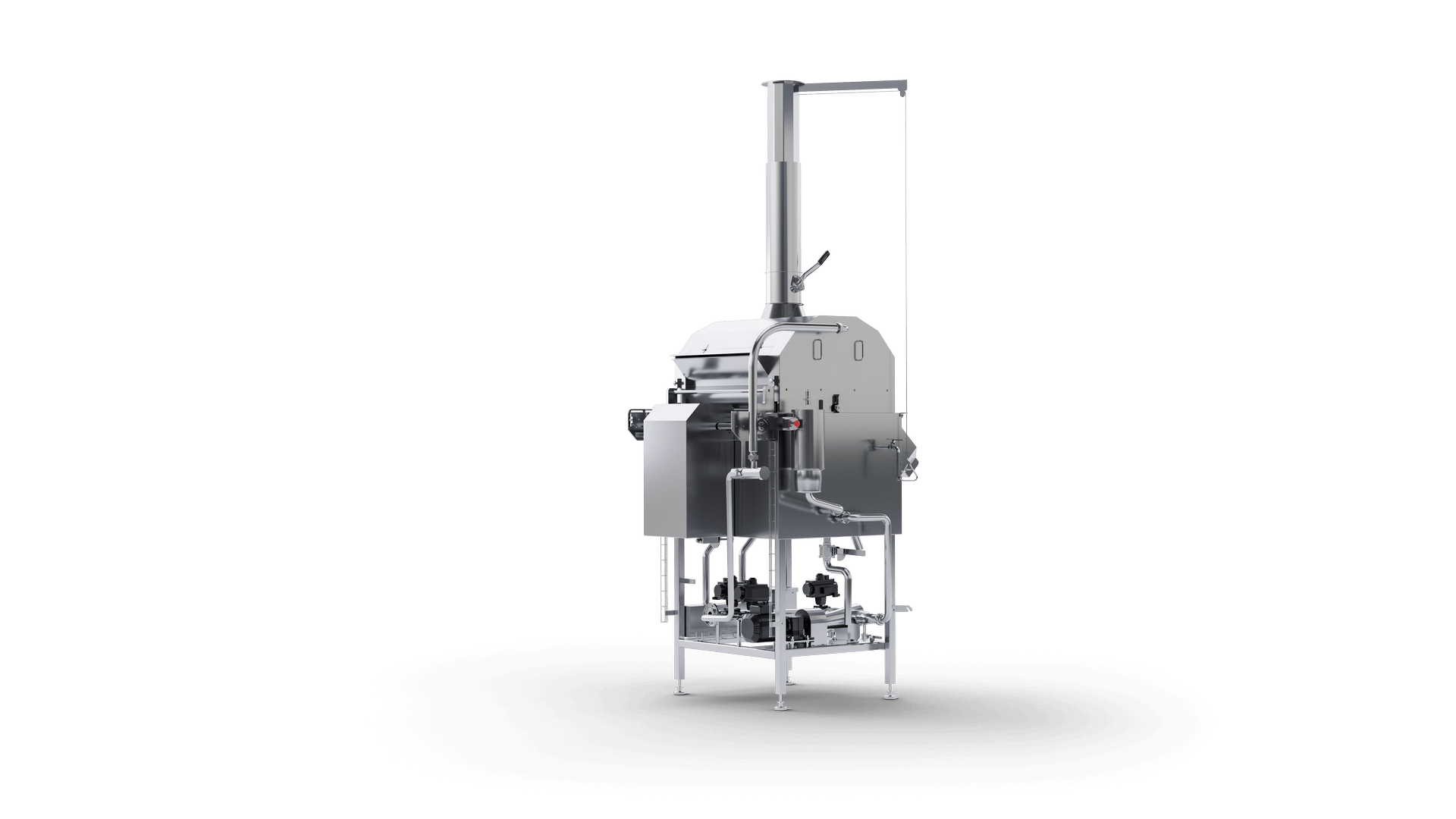

Unique pellet frying solution

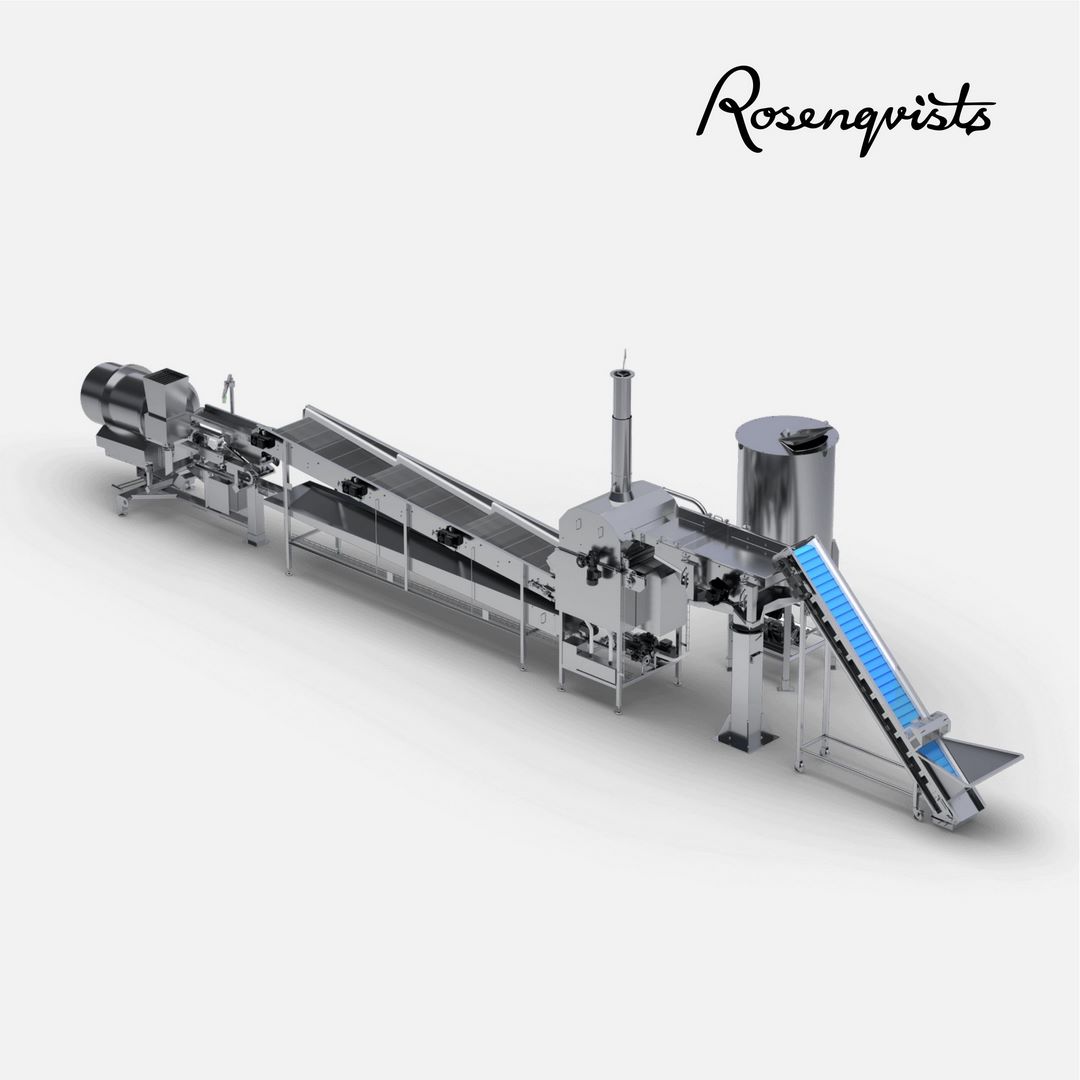

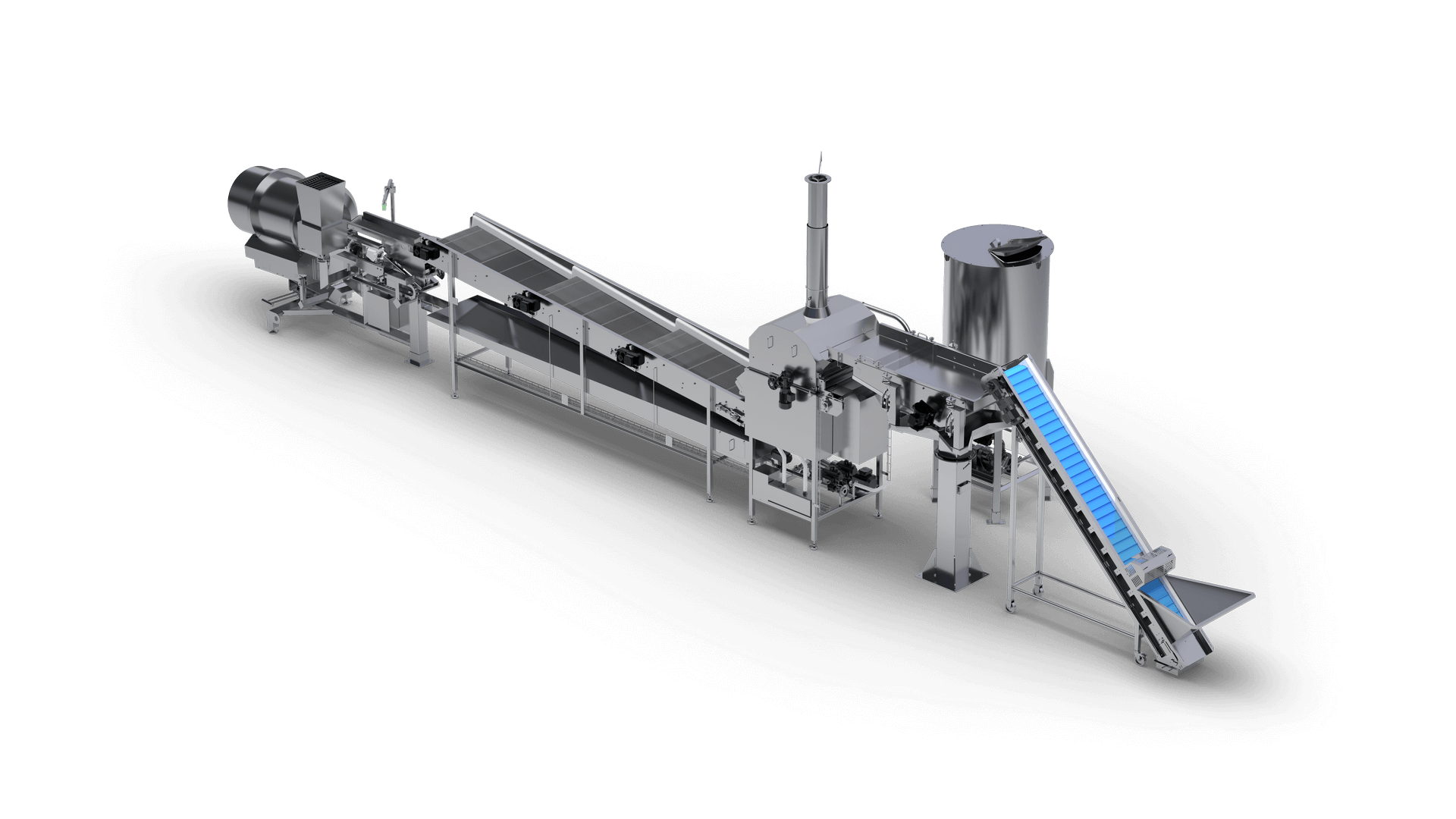

The patented Star Wheel Fryer (SWF) provides gentle handling and uniform frying of many dif-ferent pellet snacks from rings to 3-dimensional products. With the lowest total oil volume of any pellet fryer on the market, the patented Star Wheel fryer is available in three sizes with outputs from 100-750 kg/h.

Performance

The SWF system has very low total oil volume with the smallest model containing only 87 liters for a capacity of up to 150kg/h. The low oil volume equates to exceptional turnover rates at just 2-4 hours optimizing product quality and extending shelf-life. And, for added convenience, the oil level of the fryer is auto-matically controlled.

Efficient oil management

- Lowest oil volume of any pellet fryer on market • Quick oil turnover rates—just 2-4 hours

Optimum product quality

- Adjustable frying time from 8-40 seconds

- Precise and controlled frying time due to patented frying wheel

Operation

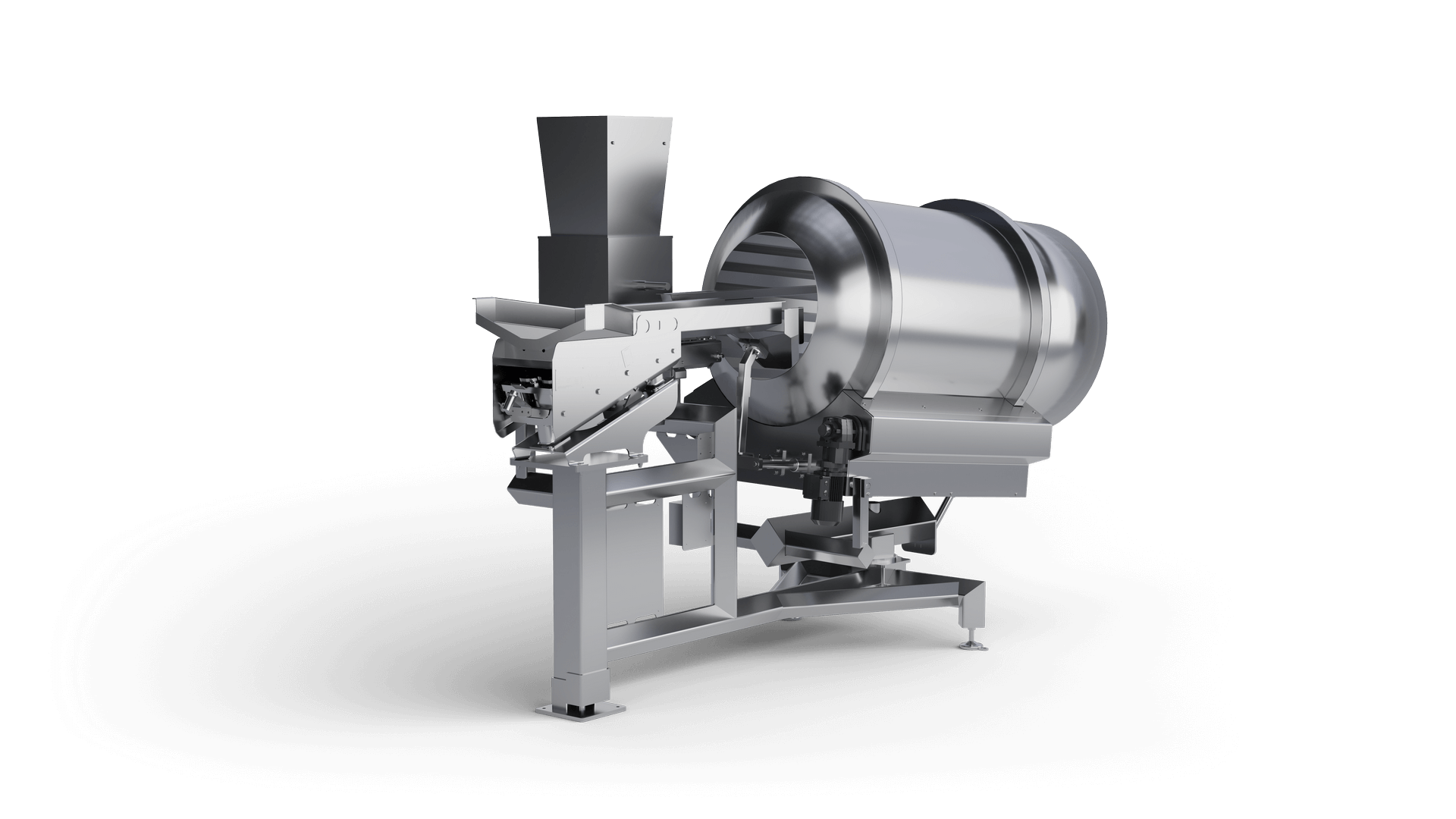

- The SWF system is designed to give you maxi-mum flexibility in the production of top-quality snacks. From rings to more complex 3-dimen-sional snacks, the SWF easily and efficiently handles a wide variety of pellet products.

- With adjustable frying time from 8-40 seconds the patented and state of the art frying wheel design, the pellets will be uniformly fried.

- An advanced controller maintains and controls oil temperature.

- The infeed system consists of an incline elevator to handle the most fragile of products and a vibratory conveyor with built in screen to remove small pieces. After the fryer the fried product passes an oil-drip-off belt prior to the seasoning process.

- The installation is simple with pre-assembly of all pipes between oil supply tank, level control and fryer.

- The SWF system is designed with easy opera-tion and CIP cleaning.

- The exhaust stack is removed allowing easy access to the frying wheel which is lifted via a motor-driven lifting system.

Photo

Equipment