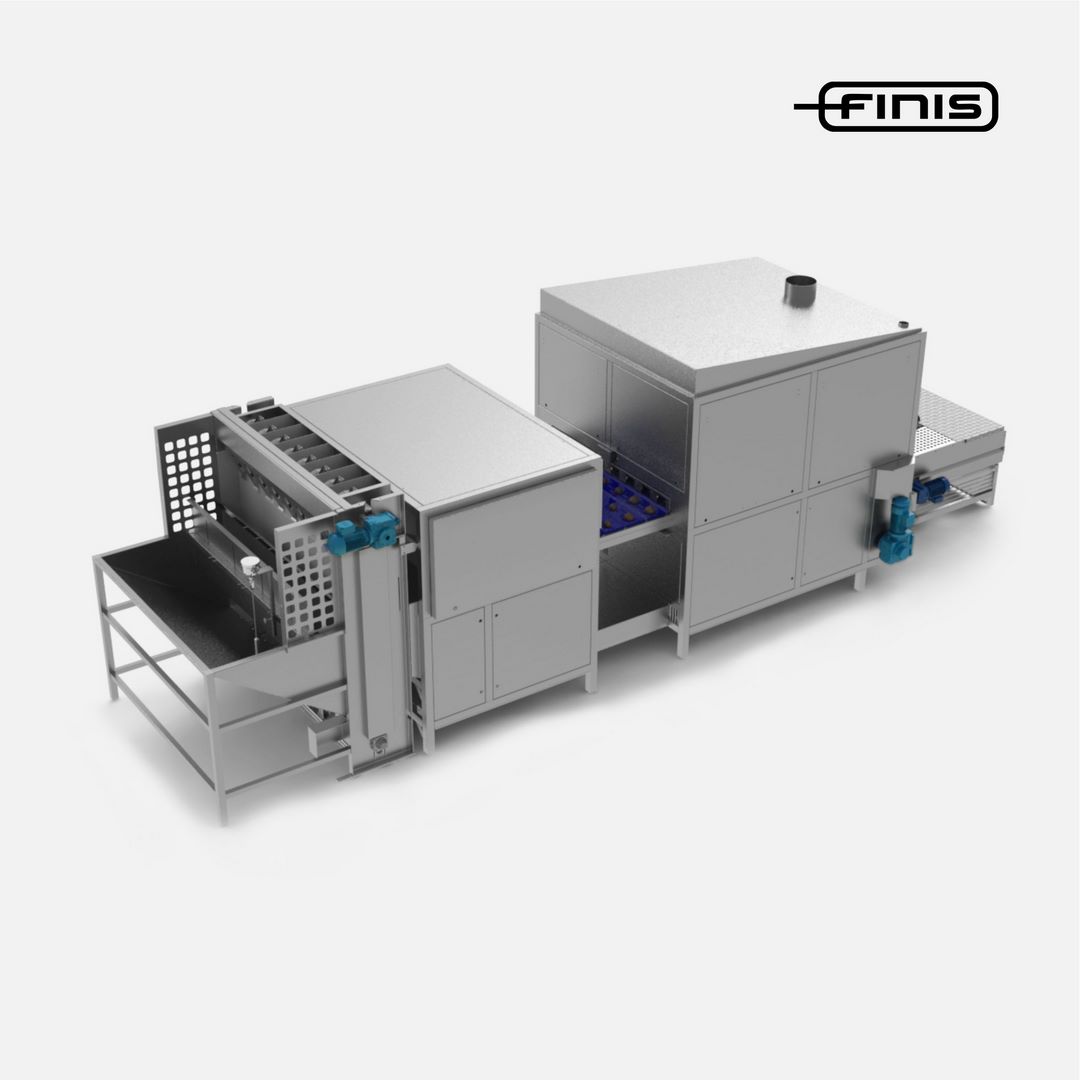

Finis is not just a supplier of peeling machines. Finis commits itself to meeting its clients’ processing needs and wishes. The TopNotch peeler by Finis has proven to be the most efficient three-stage onion peeling machine. It features sustainable processing technology, which ensures maximum productivity and reliability. Onions are fed by an automatic feeding belt and have to be positioned top-tail wise, by hand or automatically with the new vision technology. They are transported through the machine by means of a transportation chain with indexing plates. They are notched, topped and tailed and finally peeled with an air blowing system. The perfectly peeled onions not only look good, their superb microbiological state ensures a long shelf-life. Thanks to a minimum of labour, easy cleaning and low maintenance, the machine is very cost-efficient.

The TopNotch peels up to 12.000 onions per hour.

Automatic bow orientation system

Finis is proud to introduce the first Automatic Orientation System for onions in the world. After significant investment in research and development coupled with the extensive knowledge and experience in the food processing industry we have succeeded to supply towards the needs of our customers.

As an ambitious family owned company we all work towards one future. We do not develop to rival our competition, we develop to help our relation rival theirs.

This new innovation can feed a peeling line and double the capacity of its predecessor, providing up to 6,000 onions per hour per person. The onions are fed into an orientation unit. Above this unit, a camera is continuously taking pictures. A computer processes these images and locates the top and tail position of the onion. It then controls the orientation unit and the onion starts to rotate until it is in the correct position.

Coring system

The new coring system removes the top and tail of the onion. This new way of processing ensures a higher yield. Incorporating the automatic orientation unit into a fully automatic peeling line, means that the manpower is no longer needed. With the use of this system we can improve yield up to 15%. Another advantage is that the pre size grading of the onions can be less secure.

As for some products people prefer to have the original flat cut onion. The TopNotch Onion peeler can be executed with an extra topping and tailing system so that you have the choice between coring and cutting. The switch is made within 2 minutes.

A total new concept is the tailor made system that can be added to the machine. This specially developed system will peel the onions without removing the top and tail which ensures a longer shelf life.